工藝品

Decoration

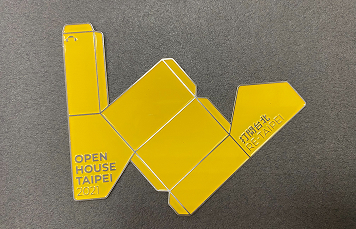

We specialize in custom metal gifts such as bookmarks and accessories, badges, keychains, commemorative coins and medals, measuring rulers, and various nameplates—tailored for thousands of schools, government agencies, creators, print & ad Company, museums, religious groups, construction firms, and corporate clients.

We provide extensive surface finishes and process planning—common effects include hairline and polish; specialty effects include brass sandblasting, stainless matte, and ploughed textures on aluminum—so each piece conveys brand value and heartfelt wishes. Let your design make a bigger impact with MicroMetal.

流程導覽

Process

From feasibility to packaging—one‑stop service for bespoke metal products.

01 Requirement Confirmation

02 Order Confirmation

03 Payment

04 Artwork Approval

05 Sample Making

06 Mass Production

需求確認

Requirement Confirmation

Visualize Your Idea

01

Visualize Your Idea

Bring dimension and craftsmanship to your metal creations. With advanced multi-process etching technology, MicroMetal can achieve:

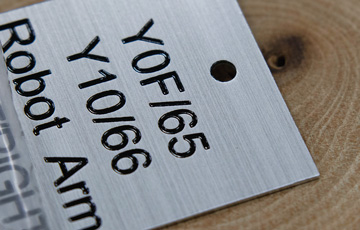

Etching

•Material thickness range: 0.1–1.0 mm

•Fine detailing for patterns, motifs, and perforated designs

1-A Half‑etch:

Shallow Etching

Deep Etching

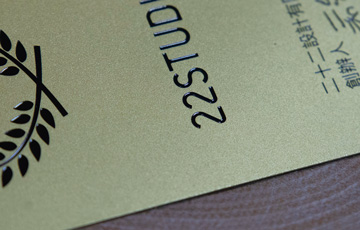

1-B Geometric RefractionPattern:

Geometric backgrounds that shimmer as the piece rotates.

Various Patterns

Pattern Details

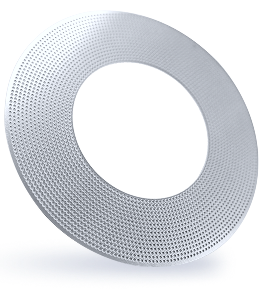

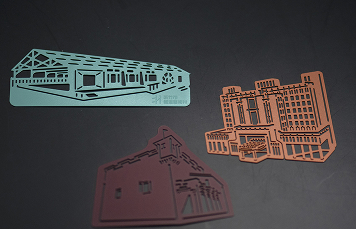

1-C Through‑Etch

Through-Etch

Deviation

Forming Methods

•Punching / Stamping & Die-Casting: Require molds; recommended for products with mass-production scale.

•Suggested thickness varies by material; please consult for actual specifications.

1-D Punching

Punching

Adhesive on Backside

1-E Stamping / Die-Casting

Stamping

Die-Casting

1-F Laser Cutting

Laser Cutting

Burn Marks & Burrs

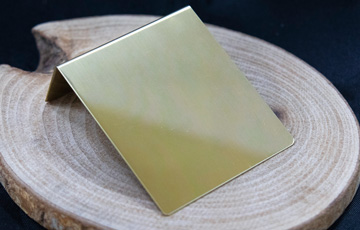

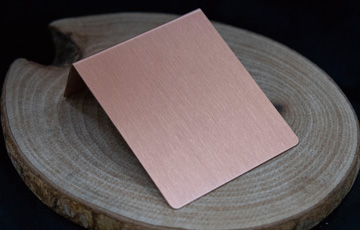

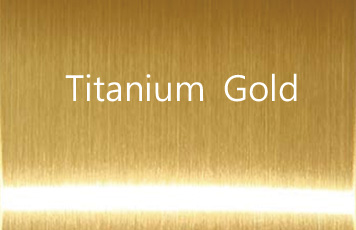

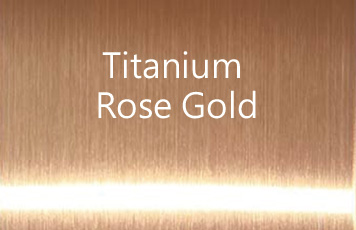

Metal Materials & Surface Finishes

Various metal surface finishes to showcase unique styles.

Style and Color

Choose the right color tones and processing methods to match your brand character and usage context.

Natural Finish (Uncoated): Preserves the original metallic luster, a timeless and cost-effective choice.

Both techniques deliver vibrant, full colors; separated by fine metal lines. Enamel paint creates a recessed effect between paint and metal, while imitation enamel lies level with the metal borders.

Full‑coat (baked enamel) highlights bold and unique designs, ideal for products with cutouts patterns.

Capable of reproducing shadows and gradients, suitable for photos, portraits, and detailed designs. Offset printing yields more saturated colors. Digital printing requires no plate-making fee, making it ideal for small-volume production.

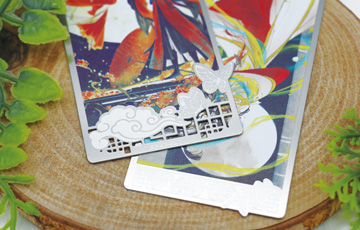

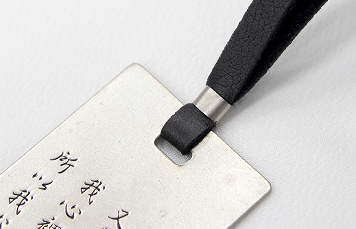

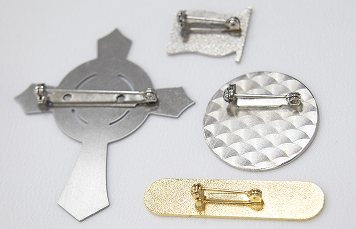

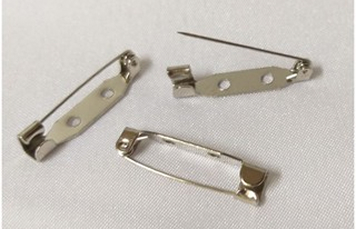

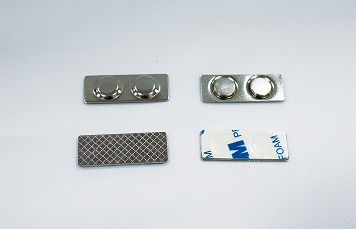

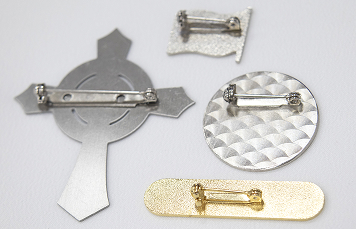

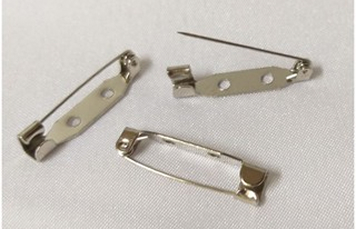

Accessories & Decorations

Optional add-ons such as chains, clasps, and decorative elements enhance both function and aesthetics.

Packaging Value-Add

A wide variety of packaging options to enhance brand image and product value.

Paper Card

Envelope

PVC Pouch

PP Bag

PE Bag

Protective Film

Adhesive Backing

Acrylic Box

Paper Box

Velvet Box

Brocade Box

MicroMetal Technology

Bringing Your Ideas to Life

- Email: service@micrometal.com.tw

- Official LINE: @534ozjnl

聯絡我們

Contact Us

MicroMetal delivers dependable quality and flexible customization.

From technical consultation to mass production, we explore the endless possibilities of metal craftsmanship with you.