Product

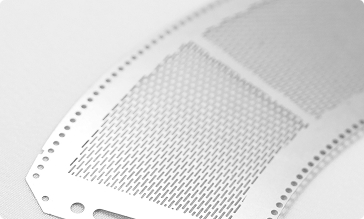

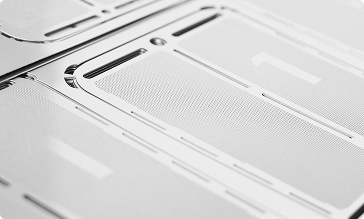

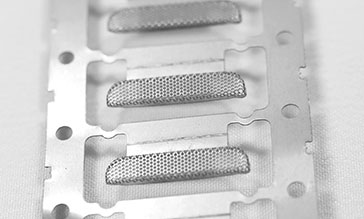

Automotive Door Sill / Scuff Plate

● Application:

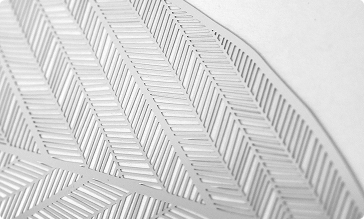

Door sill plates commonly feature polished or hairline finishes, and can integrate semi-etching or optical texture designs for a refined and distinctive aesthetic. They elevate the brand identity and provide a sense of luxury for vehicle owners.

● Material:

Various stainless steels (SUS).

產品介紹

Product Introduction

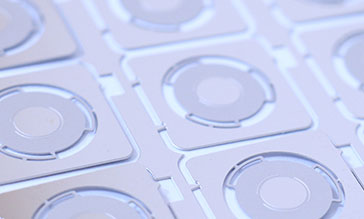

Core Manufacturing Capabilities Overview

Material: Stainless Steel, Brass, Copper, White Copper, Phosphor Bronze, Beryllium Copper, Pure Nickel Sheet

Thickness: 0.1–1 mm (through-etch type) / up to 3 mm (half-etch type)

Material Size: Within 300×400 mm or 300×500 mm for optimal precision

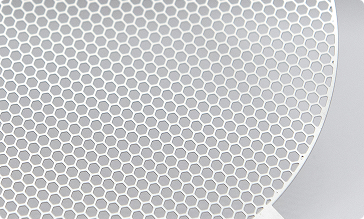

Hole Shapes: Round, Square, Hexagonal, Gradient… (customizable)

Hole Diameter: Larger than material thickness (see tolerance chart)

Dimensional Tolerance: min ±0.03 mm (larger thickness = wider tolerance)

Half-Etch Depth Tolerance: ±0.02–0.03 mm

Half-Etch Area Dimensional Tolerance: Increases with etching depth

Production Capacity: 500,000 pcs/month — fast prototyping and mass

production available

Lead Time:

≤ 1,000 pcs: 10 days

≤ 5,000 pcs: 14 days

5,000 pcs: To be discussed

One-Piece Construction

Mold-Free Etching Process

A cost-effective manufacturing method

Design Flexibility

High design freedom with both prototyping and mass production service available

Professional Consultation

Comprehensive evaluation of technical feasibility, material compatibility, and production capability

公差

Etching Tolerance Reference Table

- Metal material

- Sheet thickness

- Material size

- Layout and design of the etched pattern

(Unit: mm)

| Sheet Thickness | Dimensional Tolerance | Minimum Hole Diameter |

|---|---|---|

| 0.1 | ±0.03 | 0.25 |

| 0.2 | ±0.03-0.05 | 0.3 |

| 0.3 | ±0.05~0.08 | 0.5 |

| 0.4 | ±0.08~0.15 | 0.6 |

| 0.5 | ±0.15~0.20 | 0.8 |

| 0.5~1.0 | To be confirmed based on actual drawings and process feasibility. | |

Made in Taiwan — Precision You Can Trust

All MicroMetal’s processes are 100% produced in Taiwan, where we have been rooted for over 20 years.

We focus on every detail, supporting engineers and R&D teams to achieve ultimate precision in metal components.

Turning precision into perfection.

- Contact:service@micrometal.com.tw

- LINE Official Account:@534ozjnl

聯絡我們

Contact Us

MicroMetal delivers dependable quality and flexible customization. From technical consultation to mass production, we explore the endless possibilities of metal craftsmanship with you.