In a market that demands efficiency and precision, choosing the right process is crucial to competitiveness.

Photo‑chemical etching fits modern manufacturing needs perfectly. By using chemical solutions to corrode the metal surface, etching creates delicate semi-etched structures and through-holes. It is commonly applied to industrial components, mesh screens, and decorative metal items, and is especially suitable for handling fine perforations or thin materials.

Why Choose Etching:

1. High Precision: Etching allows precise control over depth and rate through chemical concentration, time, and temperature, ensuring hole sizes remain within tight tolerances.

2. High Forming Integrity: Etched parts are clean and uniform, free of burrs or burn marks, and maintain high design flexibility.

3. Economical and Fast: Etching allows quick prototyping and scalable production without the need for molds, reducing time and cost.

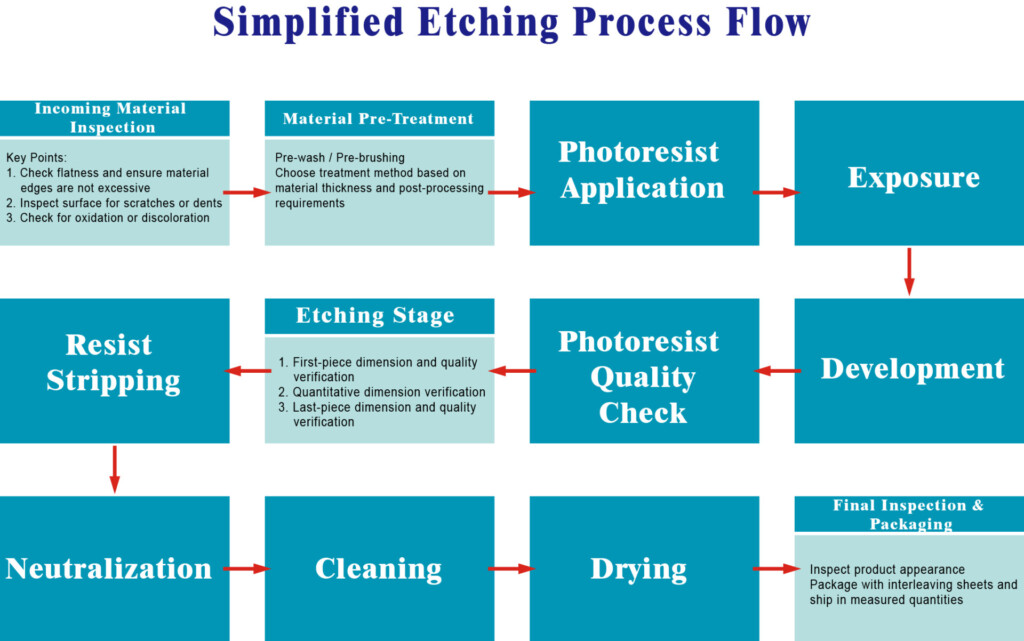

The 12‑Step Etching Process

1. Incoming Material Inspection

Check sheet condition: flatness, minimal burrs, and no scratches or oxidation.

2. Pre‑Treatment

3. Photoresist Coating

Apply a uniform photoresist layer, forming a pattern after exposure and development to protect areas from etching.

4. Exposure

Expose the coated sheet to transfers the design pattern onto the resist.

5. Development

6. Photoresist Inspection

7. Etching

8. Stripping

9. Neutralization

10. Cleaning

11. Drying

12. Final QA & Packing

Inspect appearance; pack per specification or with interleaves as required.