工業產品

Industrial Products

Rapid Prototyping • Efficient Production • Agile Market Response

Photo‑chemical etching is a fast, cost-effective solution for early-stage development, offering basic samples in one week and complex designs in two. With a monthly output exceeding 100,000 parts, we support everything from pilot runs to mass production, accelerating your path to market.

流程導覽

Process Overview

Our standardized process ensures timely and reliable product delivery.

01 Requirement Confirmation

We learn your application and technical needs in depth and provide expert recommendations.

02 Order Confirmation

Confirm specs, quantity, and pricing; countersign the quotation to place the order.

03 Payment

For the first order, pay a 50% deposit; settle the balance before shipment.

04 Artwork Approval

Verify artwork; production starts after countersignature.(Further changes incur additional costs.)

05 Sample Making

Produce samples from the approved artwork to validate requirements.

06 Mass Production

Scale up from approved samples, ensuring stable quality and timely delivery.

產品類型

Product Type

- Filters

- Radiator Meshes

- Precision Speaker Meshes

- Model Components

- 3C Product Components

- Encoders

- Electronic Connectors & Terminals

- Flat Flexure Springs

- Metal Washers & Spacers

- Heat Sinks

- Jigs / Fixture Plates

- Vacuum Coating Masks

- SMT Parts

- Beauty Micro‑Needles

- Automotive Door Sills / Scuff Plates

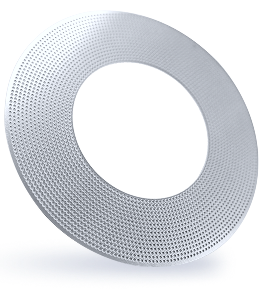

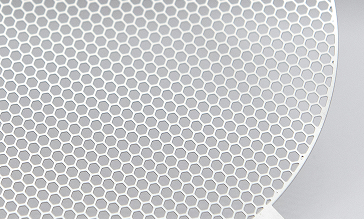

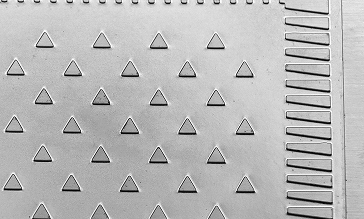

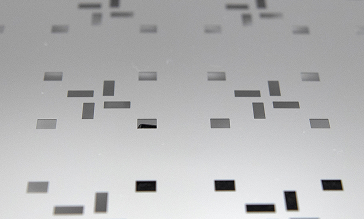

Filters

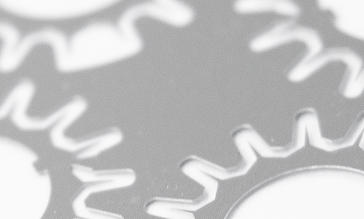

Radiator Meshes

Precision Speaker Meshes

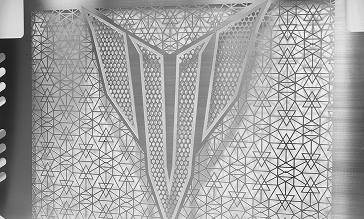

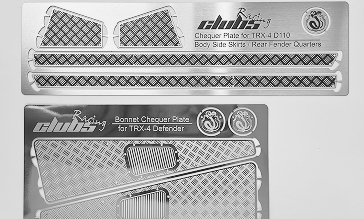

Model Components

3C Product Components

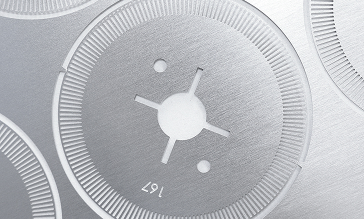

Encoders

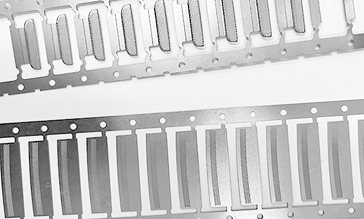

Electronic Connectors & Terminals

Flat Flexure Springs

Metal Washers & Spacers

Heat Sinks

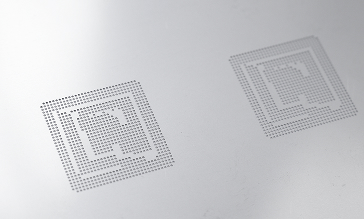

Jigs / Fixture Plates

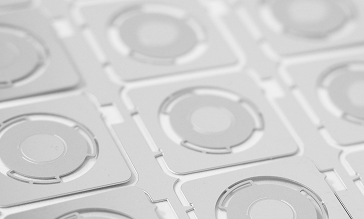

Vacuum Coating Masks

SMT Parts

Automotive Door Sills / Scuff Plates

Automotive Door Sills / Scuff Plates

應用領域

Application

Medical

3C Electronics

Automotive

Home Appliances

Machinery

Optoelectronics

使用材質

Material

Stainless Steel

Brass

Copper

Nickel Silver

Phosphor Bronze

Aluminum

Steel

Nickel

公差一覽表

Tolerance Overview

Factors Affecting Etching Tolerance:

●Metal material

●Plate thickness

●Material dimensions

●Pattern layout to be etched

(Unit: mm)

| Thickness | Tolerance | Min. Hole |

|---|---|---|

| 0.1 | ±0.03 | 0.25 |

| 0.2 | ±0.03-0.05 | 0.3 |

| 0.3 | ±0.05~0.08 | 0.5 |

| 0.4 | ±0.08~0.15 | 0.6 |

| 0.5 | ±0.15~0.20 | 0.8 |

| 0.5~1.0 | Final specifications to be agreed upon according to the actual design and process feasibility. | |

包裝方式

Package

OPP Bag

PE Bag

Counted Pack

Protective Film

Blister Pack

關於接點

About Break-off Point

What is a break‑off point? In most cases, precision parts are bridged to the sheet during etching to complete processing.

01

External Tab

External Tab: the most common type, leaving a small nib at the pre-break point, which can be reduced through post-grinding.

02

Internal Tab

Internal Tab: similar in function, but recessed within the part to preserve exterior aesthetics and prevent interference with surrounding assemblies.

03

If my part cannot have tabs, what are my options?

Tab‑less processing is available for SUS at 0.1–0.2 mm, preserving surface smoothness; however, being single‑sided etching, tolerances are looser. For more details on tabs, please get in touch with us.

We’ll safeguard your project end‑to‑end.

Contact us to build precision parts with MicroMetal.

- Email: service@micrometal.com.tw

- Official LINE: @534ozjnl

※Note: Images are for reference only.

聯絡我們

Contact us

MicroMetal delivers dependable quality and flexible customization. From technical consultation to mass production, we explore the endless possibilities of metal craftsmanship with you.