Technical Information

Aluminum

Features

- Practical lightweight material

- High ductility and variability; thus it is widely applied to trademark nameplates.

- Through different manufacturing procedures, we can create diversified and exquisite products, such as flat and 3D nameplates.

Scope of application

Trademark nameplates for 3C electronic products, automobiles, motorcycles, home appliances, machinery, etc.

Manufacturing process

- Surface treatment

- Anode

- Etching (Baking Varnish)

- Printing

- Blanking

- 3D molding

Copper

Features

- Copper has good formability; by etching or metal stamping, various surface effects can be made.

- For material selection, bronze is full and close to the color of gold. White copper and red copper are also widely used.

- Surface treatment: electroplating process allows you to have more color choices and make the surface color even fuller and radiant to enhance your product scale.

Scope of application

Electronic products, home appliances, clothing accessories, accessories, gifts and stationery

Manufacturing process

- Etching (Baking varnish / Sandblasting )

- Printing

- Rust preventives coating

- Blanking

- 3D molding

- Plating

Metal stickers

Features

Metal stickers evolved from electroforming products, which are relatively environmentally friendly.

Scope of application

3C electronic products and home appliances; can be applied to a wide range of trademark related products.

Manufacturing process

Stainless steel

Features

- Stainless steel is hard and weather resistant, and its unique metal characteristics give people the impression of durability.

- Compared with other materials, stainless steel is suitable for products that would be used for many years.

Scope of application

Mobile phone shells, speaker nets, panels, mobile phone panels, outdoor nameplates, mechanical nameplates, medical equipment, sports equipment, bicycle nameplates, stationery, rulers and measuring tools, etc.

Manufacturing process

- Etching (Baking varnish)

- Printing

- Polishing finish

- Hairline finish

- Blanking

- 3D Molding

- Plating

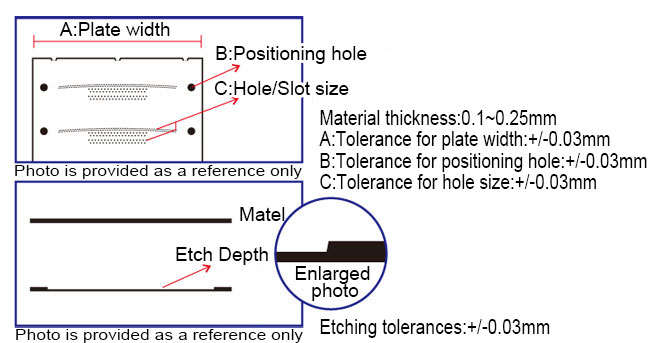

Etching tolerance value

Precision etching process

Features

Etching involves the technologies of photography and chemistry, and is one of the preferred methods for producing thin metal parts with simple or complex designs.

Chemical etching takes multi-step operation. First, the raw materials should be cleaned and scrubbed by high water pressure or ultrasonic waves. Then, the metal is laminated with photoresist film. Through UV-light exposure and etching process, a chemical etchant dissolves the unwanted sections, leaving the desired part dimensions. After the photoresist is stripped and removed, products’ surface, dimensions and tolerance are carefully inspected by electronic equipment.

Micrometal Technology Corporation takes care of every aspect of the product manufacturing process, and constantly creates customer value through high-quality products. This is what we are proud of and keep contributing to.

Scope of application

3C electronic products, home appliances and a lot more can be applied to products of all kinds of industries.

Manufacturing process

Nameplates

Features

The metal nameplates can show the beauty of metal at multiple levels through different processing combinations. The metal's unique texture gives people the impression of high fashion and durability, and increases the added value for your products.

Manufacturing process

- Surface treatment

- Anode

- Etching

- Stamping

- Die Casting

- Electroetching

Metal bookmarks & Metal decorative

Features

Metal bookmark is a must-have item for print-book lovers; metal decoration is practical and exquisite that potentially enhances everyone’s life quality. Different from other materials, metal bookmarks & decoration are more textured and have more preservation value. They are suitable products for gifts and personal use.

Manufacturing process

- Surface treatment

- Anode

- Etching (half-etch/full-etch)

- Baking varnish

- Direct printing

- Over printing

- Sandblasting

- Rust preventives coating

- Plating

- Blanking

- 3D molding